Overview

During my Summer 2025 internship at Metex Heat Treating Ltd., I was the Project Lead for the implementation of Steelhead at its sister company Exactatherm Ltd. The objective was to deliver a secure, intuitive, and role-specific platform that could be adopted seamlessly by all employees—from shop floor operators to management. Given Exactatherm’s role as an aerospace heat treater, every stage of design and deployment had to comply with strict aerospace quality standards, as the components processed would ultimately be used in aircraft. This required meticulous planning, hands-on execution, and comprehensive employee training.

Software & Process Development

- Data Migration: Transferred 35,000+ aerospace-regulated customer files from the old ERP system, ensuring compliance with 10-year retention requirements

- Automation Scripts: Created macro scripts via AutoHotKey to parse and export records into a receiving folder, then engineered a Python code to scan and relocate each file into its correct directory creating a new digital filing archetecture

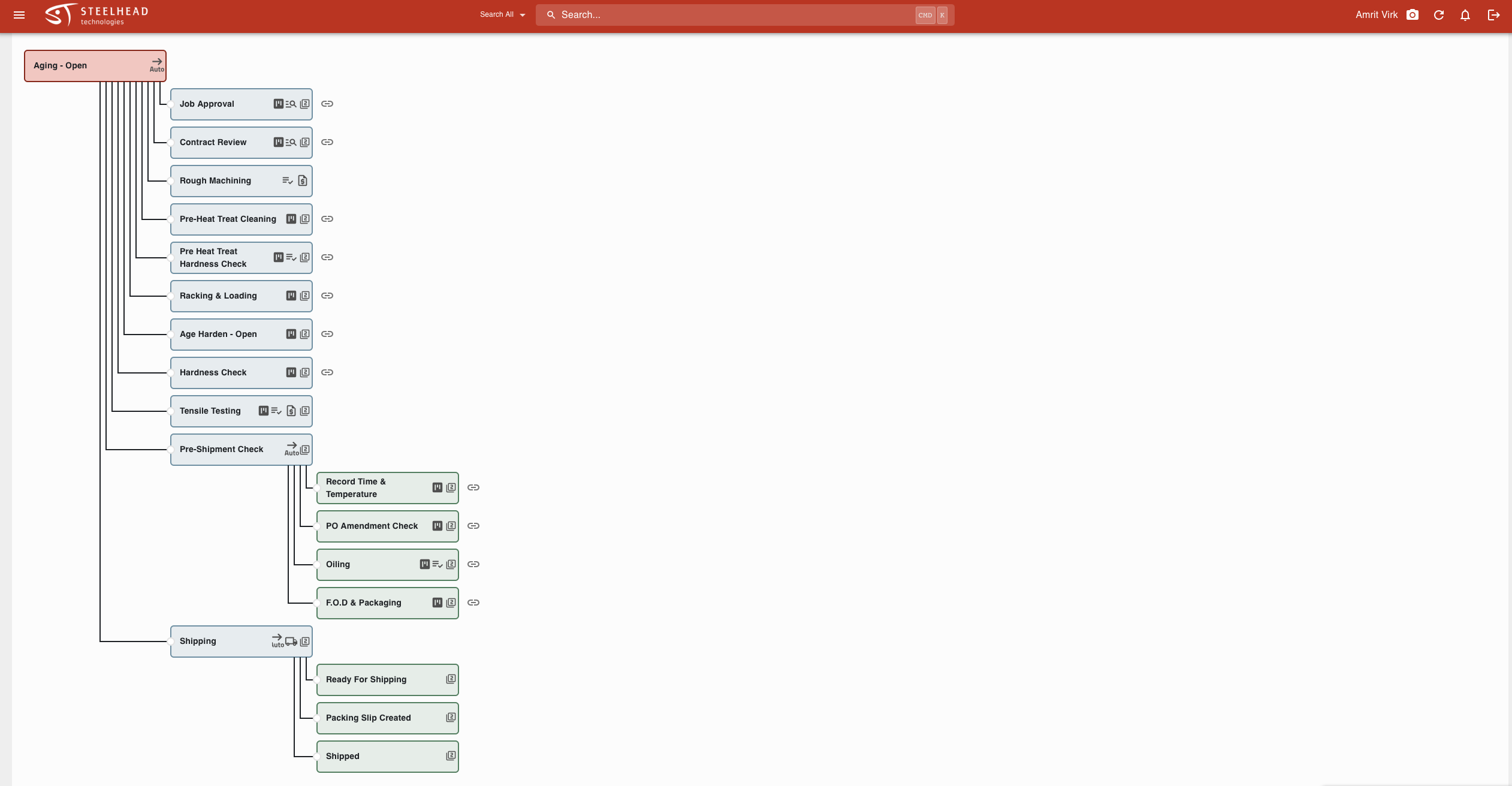

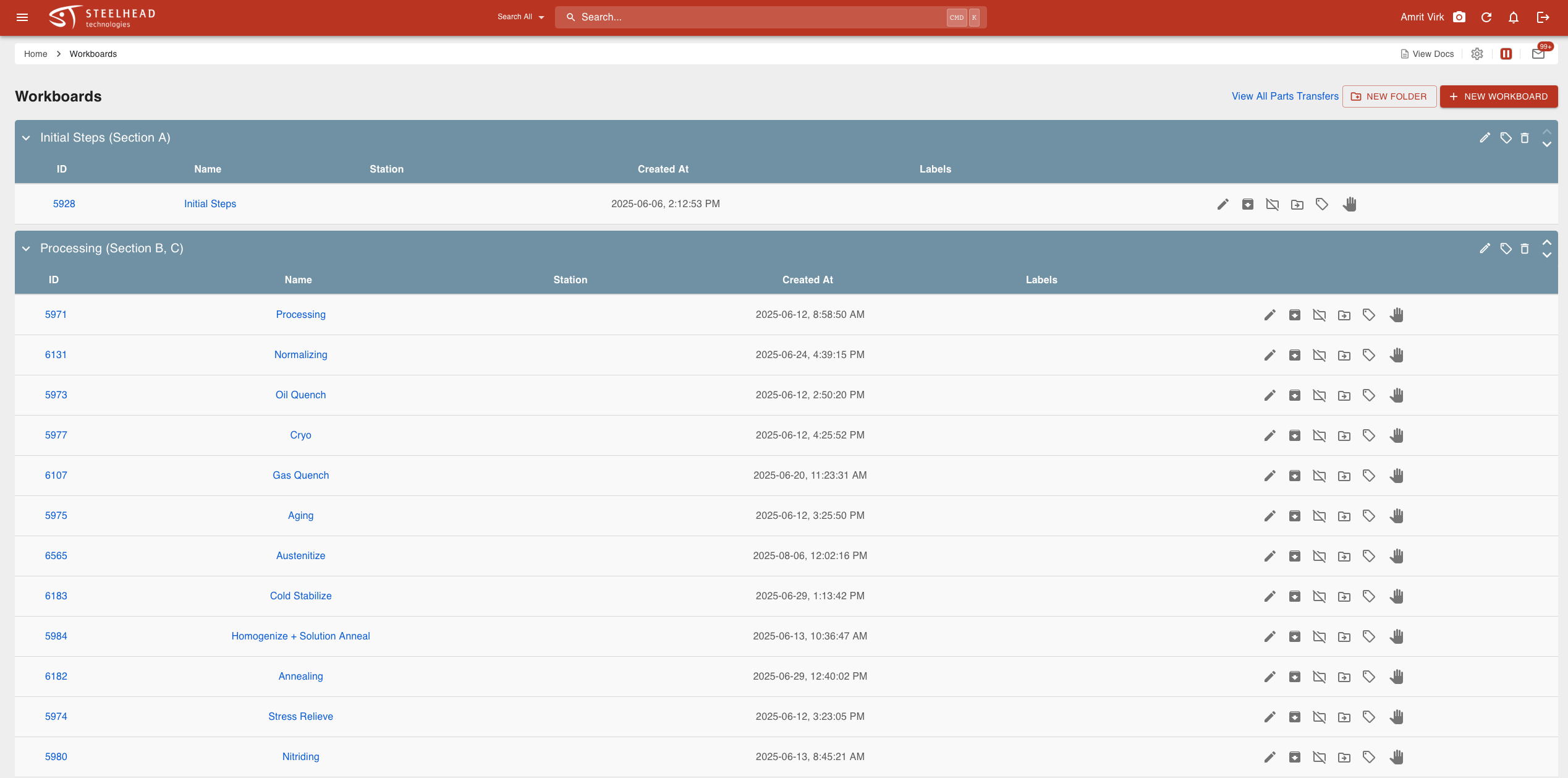

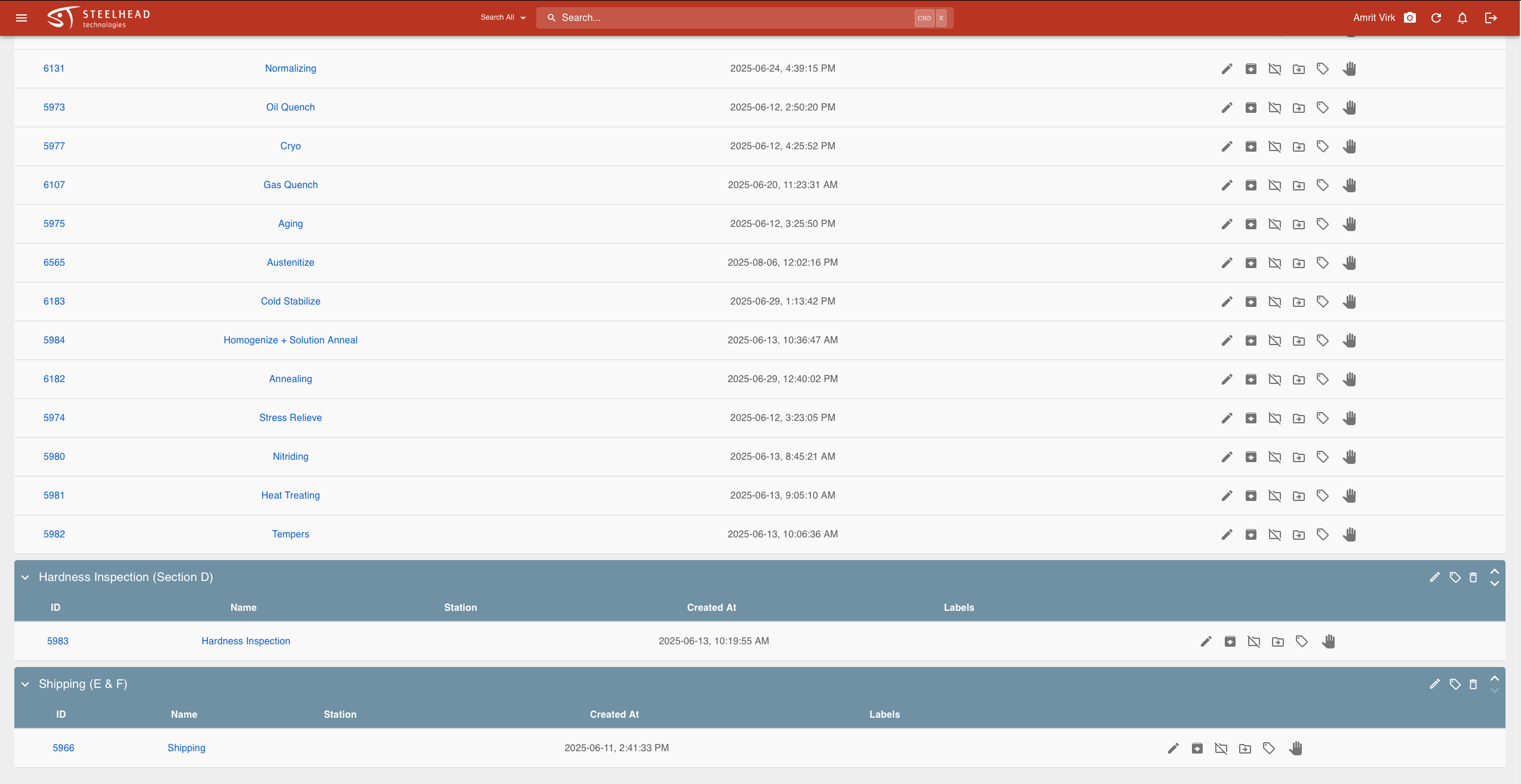

- Backend Design: Developed logic flows, process maps, and prototypes to streamline workflows—resulting in a 20% dock-to-dock time reduction

- Security & UI: Implemented role-based access controls (RBAC) to enforce permissions by role and designed a minimal, task-focused UI to improve usability

Hardware, Networking & Deployment

- System Rollout: Conducted on-floor stress testing with mobile devices to identify coverage gaps, leading to the installation of two additional router access points

- Device Management: Procured and configured seven company iPads using a Mosyle MDM environment, ensuring all devices were secure, synchronized, and compliant with IT standards

- Ergonomic Workstations: Designed and deployed optimized workstations across all departments to improve speed, accuracy, and operator comfort

- Training & Adoption: Led cross-department onboarding sessions to ensure smooth adoption across operations, quality control, and administration

Impact

Delivered a fully integrated ERP solution that improved operational efficiency by over 40% and reduced process time by 20% across departments. The system is now the backbone of Exactatherm’s operations, enabling real-time data access, streamlined workflows, and enhanced compliance with aerospace standards.

35,000 +

Customer Files Migrated

+40%

Increase in Overall Workflow Metrics

Average Dock to Dock Time Per Process

Comparison in DaysTools Technologies & Skills

- Steelhead Technologies

- Software Design

- Process Design

- Data Migration

- Python

- AutoHotKey

- Automation

- Leadership

- Workflow Optimization

- Project Management

- Training & Educating

Challenges

The company was transitioning from an older software system that had been in use for over 20 years, so ensuring that the migration to Steelhead went as smoothly as possible was my utmost priority. Each department presented its own set of unique challenges and issues, all of which needed to be addressed to ensure full functionality.

Specifically, one of the primary issues I faced was creating every single process and spec used on the production floor. This required me to learn and understand the manufacturing and material sciences side of the business to ensure that everything was created to specification. It involved extensive collaboration with the quality and production managers to verify that my work was correct. Another area where I faced challenges was in the invoicing and sales department. With little prior experience in this area, I was further faced with difficulties in implementation, as I had to ensure that all numbers were reported accurately and that invoices were reaching customers.